Monday, on the warehouse floor: “Did you get this alert that just popped up on my News app? A recession is coming any day now.”

“I did see that. And didn’t one of our biggest clients cancel half its order last month?”

“The writing is on the wall, I guess. How are the folks upstairs going to help us get this inventory out the door?”

Tuesday, in the boardroom: “OK, everybody, good news finally. The Dodge Momentum Index pointed back in the right direction in October. Forget what I said about slashing prices on stale inventory.”

“Uh, boss, I’m seeing that construction starts actually fell 11 percent in October. Third down month in a row.”

“Cancel that lunch order.”

This fictionalized account is illustrative of the anxieties many building products distributors feel as we wind down 2019. Up, down, flat – no one can seem to get a handle on the market. Prognosticators love to throw around that dirty word: recession. Eventually, they’ll be right. But obsessing over it in this line of work can easily become a self-fulfilling prophecy.

Instead, keep in mind that a plan prevents panic. You can’t run your business reacting to every whim of the market, although, given the uncertainty and rapid change, it can feel like the only option. Deliberately choosing to pick plan over panic is easier said than done, but as outlined below, it can and should be done.

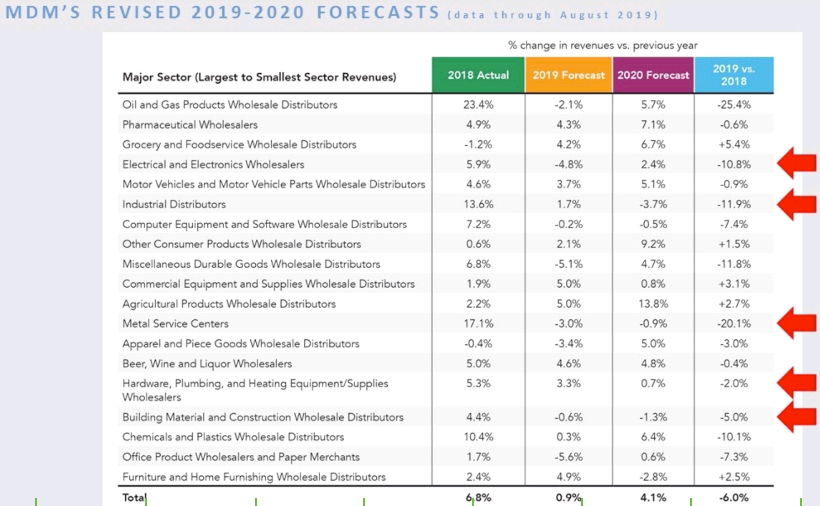

Modern Distribution Management (MDM) recently revised its 2019 and 2020 outlook for the wholesale distribution industry at large. While this chart looks rough, it projects some good news overall in 2020.

The distribution sector is projecting just under 1 percent growth in 2019, a worrisome 6 percent dip from last year. However, MDM is now forecasting a 4.1 percent rebound in 2020. For building material and construction wholesalers, a slight downturn of -1.3 percent next year does look likely. But again, this could all change – up or down – in a month. The key to remember, as Mike Marks noted in MDM’s latest webinar:

“One of the things that I find is when everybody’s sitting around talking about the market softening, a lot of people want to just crawl back in their shell and be a turtle. But that just makes you a target.”

For building products distributors that rely on the market as a leading business indicator more than other more insulated industry verticals, the reliance on large projects being greenlit and unpredictable volatile costs makes the temptation to turtle especially strong.

Be the hare, not the turtle! Consider the following three pricing and costing plays to prevent panic in 2020.

Play No. 1 - Reimagine Costing

Give your purchasing team predictive guidance on what cost deviations they should be asking their suppliers for, even for last-minute fire drills. This is will be more and more relevant as raw material costs continue to rise, and your customers have large projects that require a special bid to win. There was a time when supplier cost changes, and all the downstream pricing processes triggered by them, happened once or twice a year. Building products distributors now receive supplier cost changes multiple times per quarter and scramble to keep up. In addition to pricing issues, purchasing is often decentralized, and branch personnel have varying degrees of success when negotiating cost breaks with suppliers.

The process is arduous and fraught with potential mistakes when left to manual means. A better approach is to give your costing team guidance on when to negotiate a cost discount (frequency) and how much of a cost discount to negotiate (depth). Using data science and software is a faster and more accurate approach that looks at historical cost data and identifies appropriate discount amounts that allow distributors to share the margin pain with manufacturers. This means winning more competitive deals while staying within your profit threshold.

Play No. 2 - Reimagine Price Setting

Chasing down large projects and dealing with rapid cost changes creates a lack of relevant system prices in most building products distribution businesses. System prices often fail to accurately reflect market prices and are overly general. This leads to only 20 to 30 percent of a distributor’s revenue transacted at the more-profitable system price level, with the remainder of the revenue occurring at a discounted customer-specific price level or as a one-time deviation or override. Furthering the margin leakage, sales reps often lobby to assign nearly all their customers to the most favorable available price tier or column in the system pricing structure. In other words, every customer gets the best possible system price, regardless of the customer’s relationship with the company. This leads to rampant misassignment and additional margin leakage.

Take a closer look at how price optimization can produce market-relevant prices to drive volume or margin growth, depending on your goal and the market conditions. True price optimization means a holistic price-setting process that is grounded in reliable data science. It means your system prices are set to ensure they accurately reflect the market reality and get used by the sales team. When necessary, it then provides override guidance with guardrails to reduce over-discounting and delivers customer-specific guidance. True price optimization also allows you to pass through cost changes more effectively and granularly across the business. Finally, detailed visual analytics help to pinpoint and correct unnecessary price deviations.

Play No. 3 – Reimagine Deal Management

Your sales team is dispersed in the field. Branch managers are often mobile and unable to quickly access the latest and greatest pricing information housed on multiple spreadsheets. There are deals in flux all over the place which encompass hundreds, or thousands, of product lines and even brand-new SKUs created by sales reps. In 2020 it’s essential to have a centralized location for bids and agreements which includes intelligent recommendations for both reps and sales managers.

A modern deal management application provides visibility into and a means to update customer-specific pricing, in one central hub for reps and managers to price bids to win. We hear from a lot of companies who find out too late that they walk away from solid deals because they’ll get priced down hard on one product. For instance, one quote might contain four cuts of lumber, two types of rebar and 100 square feet of ceramic tile. The customer pushes for a steep break on one of the rebar SKUs, but not the other components. If you must be competitive and lose money on one item, but you’re getting a 25 percent margin on the rest, you take it. This seems obvious on paper. But without being able to look at a full deal holistically, with price recommendations on each line item, it can be easy to balk at one below-cost SKU price.

Effective deal management solves this and most of your workflow-based headaches, such as approvals, deal desk decisions and visibility for all relevant users.

Call these plays to ensure you have a winning plan in 2020 that holds the line on margin and costing while remaining flexible and fast to respond to market conditions as needed. Though it may seem complex, a downturn-resistant pricing and costing plan is within reach. It requires a reimagining of the legacy methods and systems that no longer can meet the demands of a rapidly changing environment. Between years of data and decades of expertise, most companies already have a vast wealth of knowledge within their four walls.

When data science is designed to solve the problems unique to building products distribution, applied to relevant in-house or other data sources, and fine-tuned with the guidance of internal pricing and costing experts, the issues of scale and speed in responding to external forces are mitigated. The technology to achieve this and the streamlined deal management necessary to take control of margin leakage exists today.